g) Surface Cleaning and Micro-Structuring with Lasers

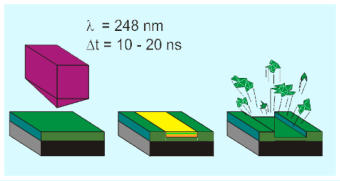

Previous studies have shown that excimer lasers are efficient and safe tools to remove securely and controlled layers of a certain thickness from the surface of icons and paintings. Excimer lasers offer significant advantages for sur- face cleaning processes, because their short wave- lengths (e.g. 248 nm) can be focused to a smaller spot size than visible or infrared light. With each pulse the UV light can remove quite pre- cisely about 0.2 µm of dirty material . In comparison: A human hair is about 50 - 100 µm thick. And for some applications even more important (different to some other laser types), excimer lasers do not release greater fractions of heat, which could cause thermal damage to surroun- ding material. These attributes make excimer lasers well-suited for cleaning sensitive surfaces like pigment lacquer, finishing varnish or art paintings, but also for manufacturing of all-poly- mer electronic components.Excimer Laser Scanning Device for Sensitive Surface Cleaning

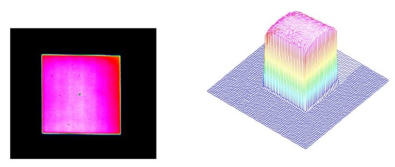

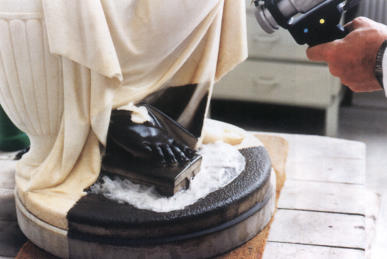

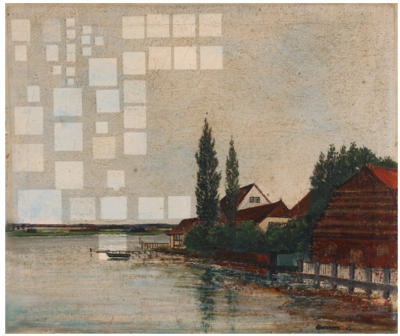

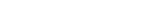

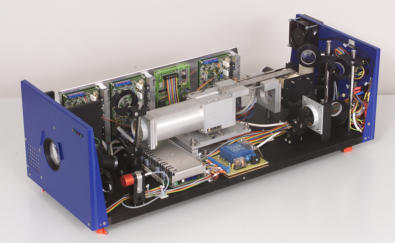

Automated, non-polluting cleaning devices are of rapidly growing interest in science and in- dustry. Particularly laser cleaning units avoiding wet chemical reactions and by this significantly reducing environmental contamination, have proven successfully and have found many new applications. Most of these laser cleaning units are designed to completely remove the top layer of a surface or the surface itself, e.g., removing paint as a preparatory step for a new sealing of the sur- face (see aeroplane or car industry). In these cases it is important to make sure, that no re- maining lacquer is left. Likewise this applies to the cleaning of stone facades, antiques or other objects suffering from dust and environmental impacts. The statue at the left was completely black like the base. Lasers, however, offer additional significant advantages compared to conventional cleaning me- chanisms: • So, soft and sensitive surfaces like paint or plastics may be treated to ablate a few micro- meters of the upper layer together with some adherent impurities without destroying the protecting function of the layer or the underlying structure. • In semiconductor epitaxi or optical coating fabrication substrates can be irradiated to re- move monolayers of water or oxygen from the surface even under ultrahigh vacuum condi- tions. • Toxic chemicals or hazardous bacteria sticking at the surface can be cracked and vaporized to sterilize instruments. • Lasers can be used to decontaminate some equipment which was radioactively conta- minated. We developed a laser cleaning unit desig- ned for an automated processing and cleaning of contaminated samples. Particularly dust, chemicals or radioactive isotopes sticking at varnish, lacquer or plastic sealing are removed together with a few µm thin film of the surface without destroying the sealing itself. While for complete removal of a sealing it may be favorable when the laser radiation penetrates into deeper layers and causes some depth effect, ablation of only a thin film requires deposition of the laser energy into the top layer of the surface. This is best realized with lasers operating in the UV, where paint and plastics show significantly increasing absorption. Therefore, we are working with a KrF-excimer laser. The key element of the cleaning device is a beam forming and scanning unit. To improve the laser beam quality for homogeneous irra- diation of samples, a beam homogenizer was developed which forms a rectangular cross se- ction with top-hat beam profile. The beam is focused down to 2x2 mm 2 and directed across the polluted surface by a beam scanner which uses two galvo mirrors. The scanning rate and by this the deflection of the beam is adapted to the pulse repetition rate (up to 1 kHz) and therefore allows an extremely fast automated processing. An accurately controlled beam positioning together with the top-hat profile ensures a very ho- mogeneous, uniform and reliable irradiation of each surface element with an almost identical laser fluence. Our investigations with this set-up show, that after optimizing the relevant laser parameters like pulse energy, peak intensity, laser repeti- tion rate, number of pulses and beam profile, an efficient cleaning without damage of the surface is obtained. A computer controlled operation of the system guarantees the uni- form and continuous cleaning as well as a comfortable handling. The unit is equipped with an adapted suction nozzle to dispose the detached particles from the surface. To quantify the cleaning efficiency and to proof the applicability of laser cleaning even for radio- actively contaminated samples varnished plastic plates were prepared, contaminated with 152 Eu at the surface. 152 Eu is favorably used as contaminating test material, since under normal con- ditions it is not radioactive but can be activated well-aimed by neutron radiation to a metastable configuration with a half-life of 9.5 h. Therefore, any handling of the plates during preparation and cleaning can be done without danger of radioactivity. The laser cleaning efficiency is determined by measuring the radioactivity of the plates before and after laser irradiation. We found that with a fluence of 1 J/cm² only one or two pulses per position are necessary to bring the initial contamination level down to less than 5%. The same set-up can also be used for cleaning of art paintings and restoration of antiques. The scanner unit directs the excimer laser radiation onto the painting and sweeps the beam across an area of 6x10 cm². For processing of larger areas the painting can be shifted automati- cally by stepper motor controlled displace units. This figure shows an oil painting as test ob- ject irradiated with different concentrations (pulses per position). It demonstrates the well controllable, homogeneous treatment and the efficiency of excimer laser cleaning of art ob- jects. It results in an appealing and bright appearance of the processed area and shows the suspicious potential for future excimer laser cleaning applications.Doctoral Theses

B. Warm Einsatz Adaptiver Optik zur Formung von Laserstrahlen School of Electrical Engineering, Helmut-Schmidt-Uiversity, Hamburg 1994 R. Meixner Herstellung und Charakterisierung wellenlängenselektiver organischer Feldeffekttransistoren School of Electrical Engineering, Helmut-Schmidt-Uiversity, Hamburg 2007 K.-H. Steglich Reinigung und Strukturierung empfindlicher Oberflächen mittels Excimerlaserstrahlung - Entwicklung und Anwendung eines Applikationsgerätes - School of Electrical Engineering, Helmut-Schmidt-Uiversity, Hamburg 2008Refereed Publications in Journals and Conference Digests

K.-H. Steglich, H. Harde Laser Cleaning of Radioactively Contaminated Surfaces Proceedings of the Conference on Lasers and Electro Optics Europe 1998, IEEE Catalog No. 98TH8326, ISBN: 0-7803-4233, Glasgow, Scotland, UK, p. 24 (1998) K.-H. Steglich, H. Harde Laser Scanner for Cleaning of Sensitive Surfaces Conference on Lasers and Electro-Optics/Europe (CLEO/EUROPE 2000), IEEE Conference Digest, CWF 57, Cat. No. 00TH8505, ISBN: 0-7803-6319-3, Nice, France, p. 215 (2000) K.-H. Steglich, H. Harde Sensitive Surface Cleaning using an Excimer Laser Scanner Conference on Lasers and Electro-Optics (CLEO 2001), Technical Digest, CTuT 7, Cat. No. 01CH37170, ISBN: 1-55752-676-1, Baltimore, MD, USA, CTuT 7, p. 233 (2001) K.-H. Steglich, H. Harde Sensitive Surface Cleaning Using an Excimer Laser Scanner Conference on Lasers, Applications and Technologies (IQEC/LAT 2002), Technical Digest, LMF 45, Moscow, Russia, p. 283 (2002) K.-H. Steglich, H. Harde Automated Surface Cleaning with an Excimer Laser Conference on Laser-assisted Micro- and Nanotechnologies (ILATA-III 2003/LAM-X), Technical Digest, PSII-1, 2003, St. Petersburg, Russia, p. 38 (2003) K.-H. Steglich, H. Harde Rapid Excimer Laser Cleaning of Plane Objects Conference on Lasers and Electro-Optics/Europe (CLEO/EUROPE 2003), Conference Digest (CD-ROM, Volume 27E), CK5W, ISBN 2-914771-15-0, Munich, Germany, p. 106 (2003) K.-H. Steglich, H. Harde Art Cleaning by Excimer Lasers Eurolaser 1/2004, Verlagsgesellschaft Grütter GmbH & Co. KG, Coburg, ISSN: 1430-8274 (2004) P.H. Thiesen, R. Meier, T. Fedorkova, K.-H. Steglich, H. Harde, B. Niemeyer Die Bestimmung der Dicke laserbehandelter Polymerfilme mittels Ellipsometrie Chemie Ingenieur Technik 2004, 76 No.9, Wiley-VCH, ISSN 0009-286X, p. 1385 (2004) P.H. Thiesen, R. Meier, T. Fedorkova, K.-H. Steglich, H. Harde, B. Niemeyer The Thickness of a Modified Polymere Film - An Ellipsometric Study 12. Wolfgang-Ostwald-Kolloquium, Kiel (2004) R. Meixner, R. Wille, P. Schertling, H. Goebel, H. Harde, K.-H. Steglich, F.A. Yildirim, W. Bauhofer, W. Krautschneider Bottom Gate Organic Field Effect Transistors Made by Laser Structuring Organic Electronics 7, pp. 586–591 (2006) K.-H. Steglich, H. Harde Oberflächenreinigung mit Lasern Uniforschung, Forschungsmagazin der Helmut-Schmidt-Universität Hamburg, 14. Jahrgang, S. 12-15 (2004), ISSN: 0940-8061Contributions on National Conferences and Meetings

K.-H. Steglich, H. Harde Reinigung kontaminierter Oberflächen mit Hilfe eines Excimer-Lasers Frühjahrstagung der DPG, Sektion Kurzzeitphysik, Bayreuth, 10. März 1998, Verhandl. DPG (VI) 33, 305 (1998) K.-H. Steglich, H. Harde Excimer-Applikationsverfahren zur sensitiven Reinigung radioaktiv kontaminierter Oberflächen Frühjahrstagung der DPG, Fachverband Kurzzeitphysik, Heidelberg, 18. März 1999, Verhandl. DPG (VI) 34, K 7.6, 288 (1999) K.-H. Steglich, H. Harde Reinigung radioaktiv kontaminierter empfindlicher Oberflächen mittels eines Excimer-Lasers Poster Norddeutsches Laserkolloquium 1998, Hannover, 9. Dezember 1999 K.-H. Steglich, H. Harde Excimer-Laser-Scanner zur sensitiven Reinigung radioaktiv kontaminierter Oberflächen Frühjahrstagung der Deutschen Physikalischen Gesellschaft, Fachverband Kurzzeitphysik, Bonn, 6. April 2000, Verhandl. DPG (VI) 35, D3 (2000) K.-H. Steglich, H. Harde Excimer-Laser-Scanner zur Reinigung empfindlicher Oberflächen Frühjahrstagung der Deutschen Physikalischen Gesellschaft, Fachverband Kurzzeitphysik, Bochum, 18.-21. März 2002, Verhandl. DPG (VI) 37, D3 (2002)